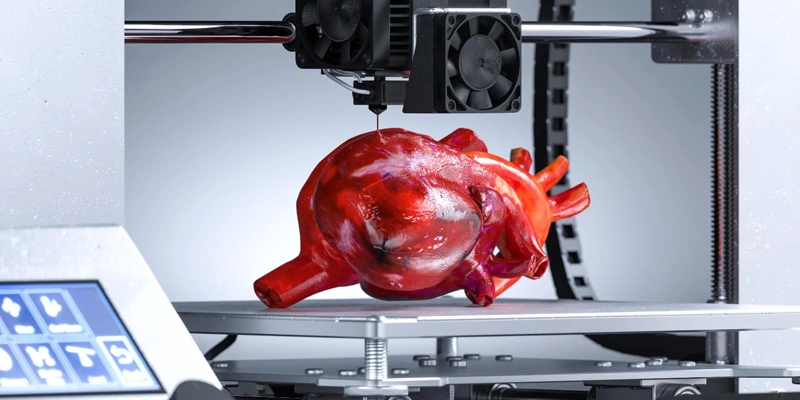

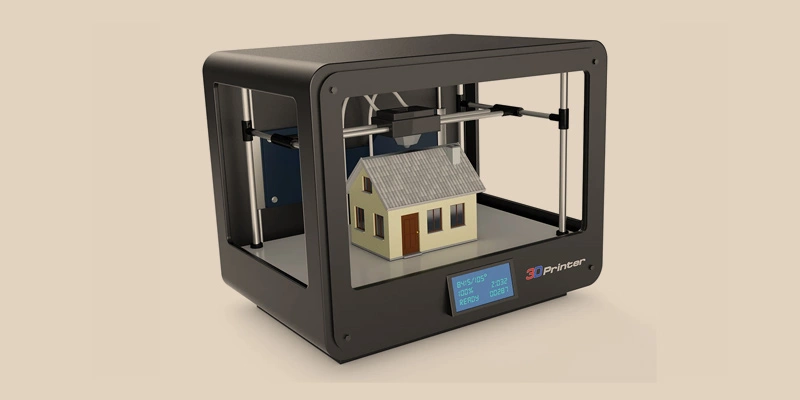

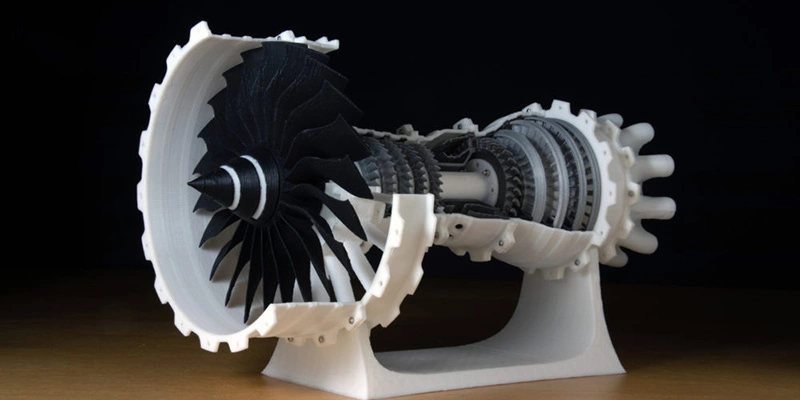

3D printing is gaining popularity in numerous sectors as it helped industries to fabricate things that were never possible with traditional manufacturing. With its help, you can print almost anything at the comfort of your home or workspace. You just have to invest in buying a 3D printer, and within minutes, you can easily print the 3D models of various objects like machine spares, furniture items, clothes, and even human organs.

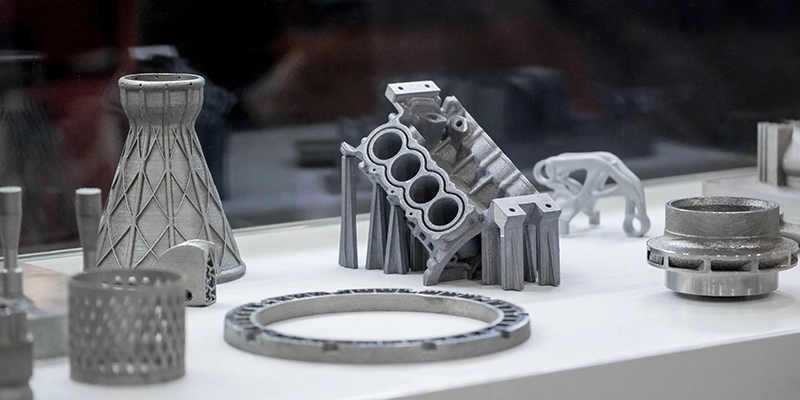

3D Printing, also known as additive manufacturing, is the process of building 3D objects by stacking successive layers of materials on top of each other. It originated in the late 1980s and was first used commercially in the automotive and aerospace industry for rapid prototyping. Whether you are new to the technology or want to get your doubts cleared, this guide will provide you the general idea about the concept of 3D printing, programs involved, popular file formats, and its different area of application.

Software for creating print-ready 3D models

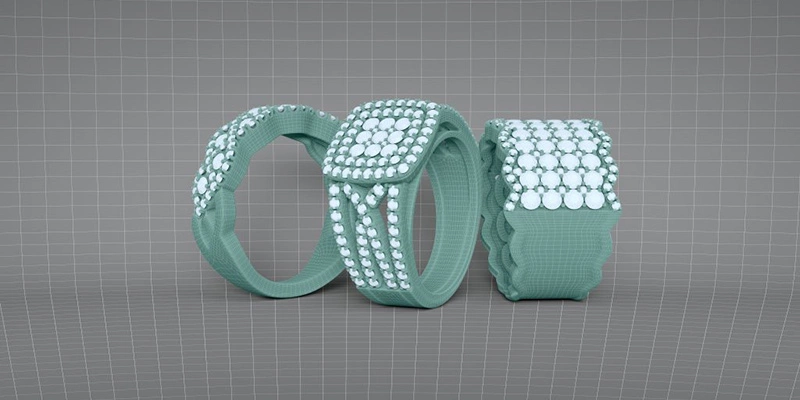

Knowing about the best tools and software programs will help you to quickly finish up your design process and create the desired prototype. There are various types of 3D modeling software that you can use depending on your objective and functionalities you want to incorporate in the model.

Some programs allow for the creation of print-ready models. Other programs just facilitate the creation of 3D designs that need to be further processed through another specialized program. The model should have a single mesh with all its seams joined perfectly together.

Below are some of the important software programs that can be utilized for creating 3D models ready to print.

Techniques for 3D Modeling

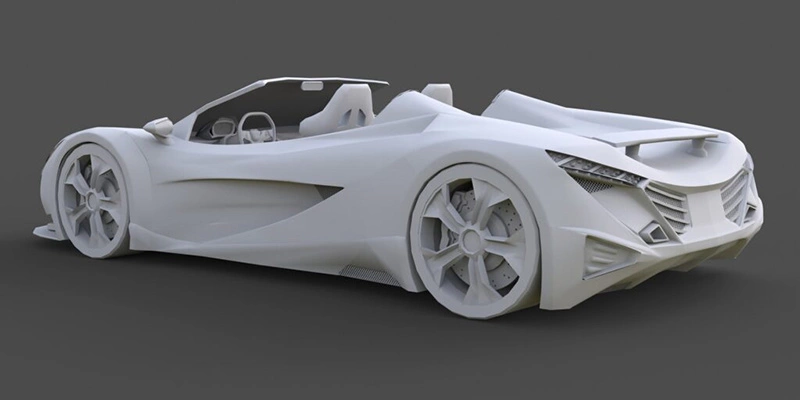

You can perform 3D product modeling with Non-Uniform Rational Basis Spline (NURBS). You can create smooth images with non-pixelated edges. NURBS has an advantage over polygon mesh based programs. When you scan an object in CAD software, initial scanning is done with NURBS.

You can also use polygon modeling to render the models. Edges, vertices, and faces of objects can be manipulated. Mesh-compatible smooth images can be rendered easily with polygon modeling. STL conversion is also not required. You can use triangle mesh computation for modeling any three dimensional object.

3D Printing File Types

In a 3D file format, the model-related information is stored in the form of binary data or text. Some of the most popular file formats used in 3D printing are

- Collada

- OBJ

- Fbx

- 3df

- Step

- STL

- IGES

- VRML

- X3D

- Obj

- STL

- 3MF, and

- AMF

These 3D file formats are widely prevalent as they are compatible with major software and CAD programs. Besides, these are well-documented and compatible with different hardware as well. Thus, depending on your use, you can choose the desired format of your choice.

3D Printing in Various Industry Verticals

Thus, by leveraging the advanced features of 3D printing, it is now possible to attain quality, reliability, and overall value for your business operations. Also, it has become a favorable tool for many individual users, as 3D printing programs are becoming more flexible and easy-to-use.

Therefore, no matter what your skill level is, utilize its potential to the maximum extent to produce outcomes that would redefine the design trends in the times to come.